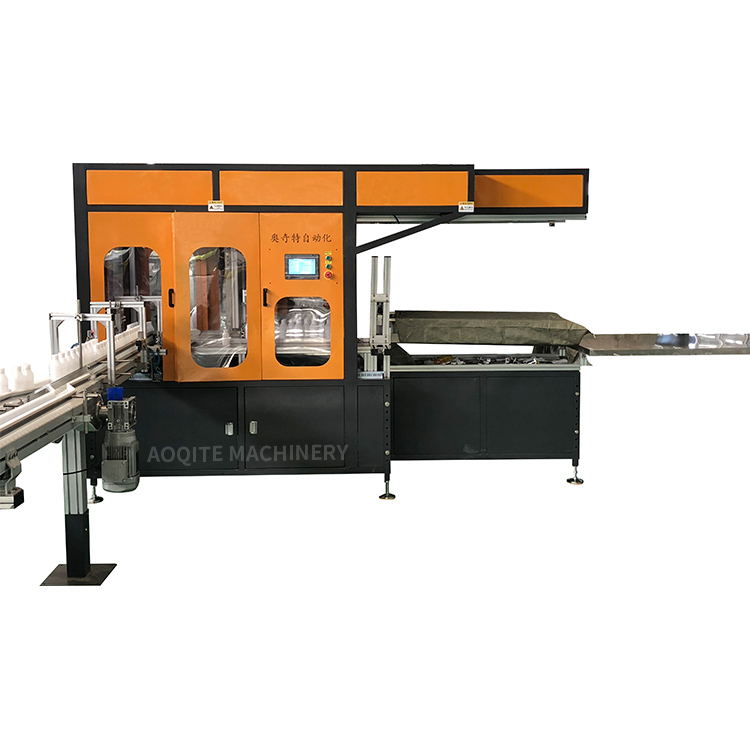

Description

Extrusion Blow Molding Machine,

Extrusion Blow Molding Machine,

- High Production Efficiency: It can complete the production of a large number of hollow plastic products in a short time, meeting the needs of mass production.

- Good Product Quality: The products produced have uniform wall thickness, high strength and good stability, which can meet the use requirements of different industries.

- Wide Range of Applications: It can produce various hollow products of different shapes and sizes, such as bottles, barrels, cans and automotive parts, which are widely used in the packaging, automotive, medical and other industries.

- Energy Saving and Environmental Protection: With the development of technology, many plastic blow molding machines now adopt energy-saving technologies, such as frequency converters and electromagnetic heaters, which can effectively reduce energy consumption and meet the requirements of environmental protection.

-

Applications

- Packaging Industry: It is widely used to produce various packaging containers, such as beverage bottles, oil drums, medicine bottles and cosmetic bottles.

- Automotive Industry: It can be used to produce automotive parts such as air ducts, fuel tanks and bumpers.

- Household Goods Industry: It is used to produce various household products, such as buckets, basins, storage boxes and children’s toys.

- Medical Industry: It is used to produce medical products such as medical bottles, infusion bags and blood storage bags.

Reviews

There are no reviews yet.