Description

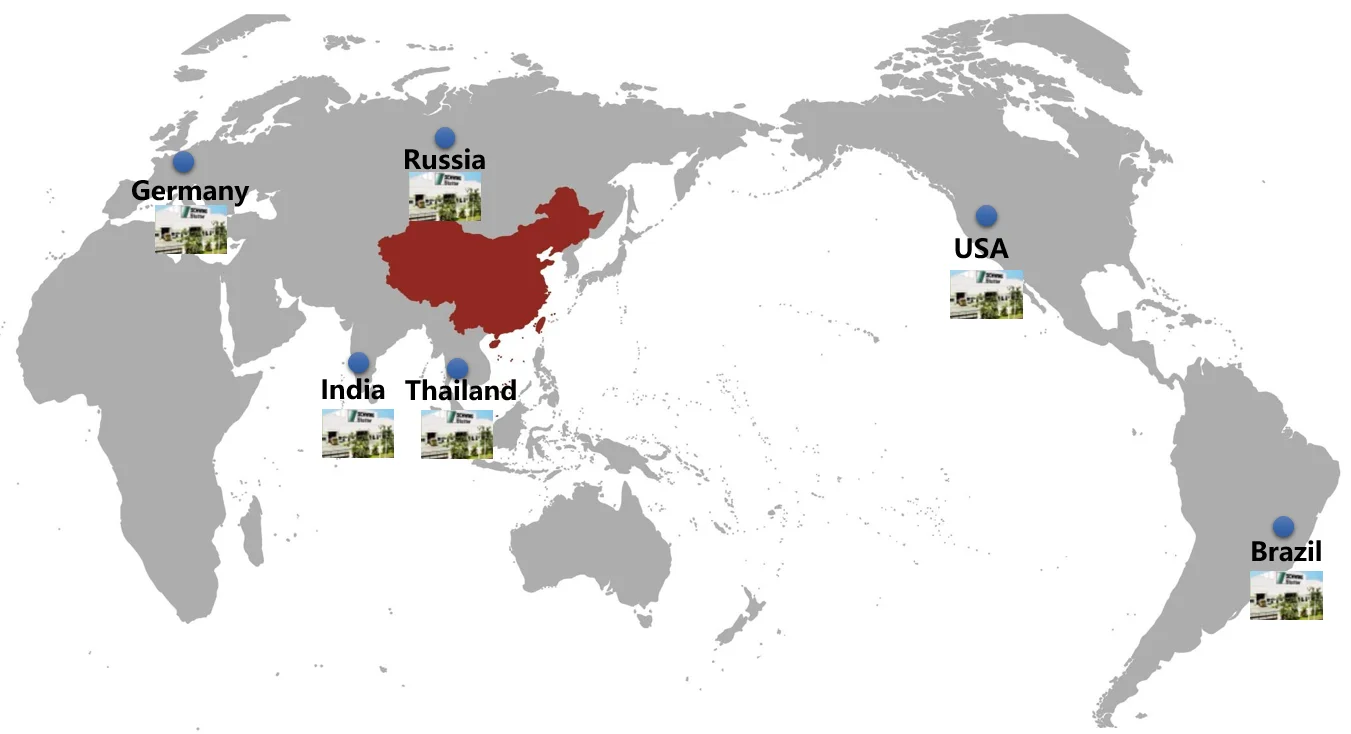

ABOUT US

baling water purification equipment and so on At present, we have a professional team, many different departments and factories to produce various machinery and daily necessities, serve customers and occupy the market!!

If you have any interests in our products ,you are welcome to

contact us!best wish to you

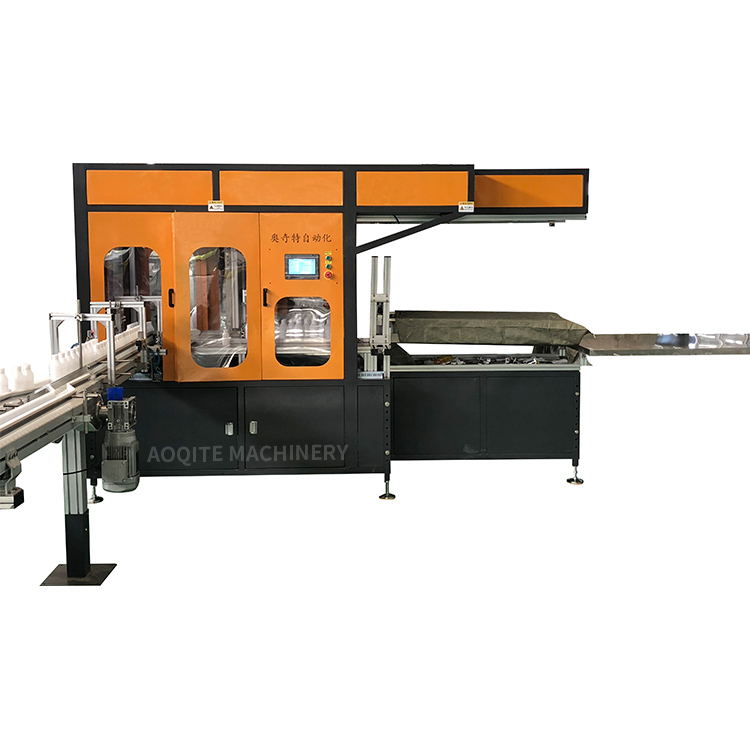

AUTOMATIC VACUUM FORMING MACHINE

Usage:

The machine is suitable for making all size packing containers ,in open-type with thin-wall ,by using roll-sheet , under

high-speed vacuum suction-forming processing .The products out of this machine can be used for the package of foods

.native-products,tourist-goods,textile,medical, toy,cosmetic,electrical elements and daily used hard-ware ,etc .

Sheet fit to the machine

Starch-deposit sheets ,light-deposit sheet ,environment sheet APET ,PETG .Color sheets :PVC,HIPS,PET,PS,PP, EPS,

etc.Fiber-coating-sheet.

Structure features

1.The machine combine with mechanical ,pneumatic and electrical integration fully computer control .Touch Screen easy operation.

2.Inverter Feeding Driving ,length stepless adjust ,Feeding accurate, stable and high speed.(Max Feeding Speed 1000mm /per second)

3.Temperature Control system , fully computer intellectual temperature control , short heating time ( only 3 min from 0-400 degree

) ; stable ( not effect by outside voltage and temperature fluctuate is less than 1 degree) ; lower power consumption 15% , longer

life of far infrared ray ceramic heater.

4.Heater has deflection over structure ,which could close whole row of the porcelain heaters when the width of sheet is≤580mm.It

can reduce power consumption 16%.

5.Heating Temperature control , individual heating control , Touch Screen input , mini-adjustment precision and heating

temperature uniformity .

6.Advance feeding with the heating time automatic memory function ,machine could start production from the first feeding .

7.Two-step vacuum ,Two time of up-mould ,Mould Shaking Function ,Mould delay .

8.Up/down Mould electric stroke adjust ,easy to adjust under the mould matched situation .It could improve the accurate of molding

and quality of finished production .

9.Back acting plate position motor adjust .

10.Up/down mould match into cushion ,avoid cushion and improve the match speed .

11.Up/down Guiding Leader with self-lubrication bearing couple .stable production and durable structure ,it could assure the high

quality of finished products.

12.Heaters with moving-out structure ,could move out under the malfunction situation ,it could save the sheet materials .

13.Cylinder Sheet Loading structure ,easy for workwoman operation .

14. Cutting unit with double clamping cutting function ,could produce Male/Female and various different of products slide cutting

.

15.Movement Guide Pole, easily stack .

Reviews

There are no reviews yet.